A safety Alert applicable to All aircrafts with Airframe Emergency Parachute System BRS 1350 HS installed, and with S/N up to F-13-09-04, C-11-11-02,A-12-04-33, included.

Please refer to This Alert

Aircraft with higher S/N are not affected.

A safety Alert applicable to All aircrafts with Airframe Emergency Parachute System BRS 1350 HS installed, and with S/N up to F-13-09-04, C-11-11-02,A-12-04-33, included.

Please refer to This Alert

Aircraft with higher S/N are not affected.

Flight Design has issued a Mandatory Safety Alert (SA) issued December 19, 2013. For Fuel Injected CTLSi aircraft.

This Safety Alert requires you to determine, by reference to engine type – Rotax 912iS, if your aircraft has been affected. Detailed information is available on the Flight Design webpage: http://www.flightdesign.com/index.php?page=service, as contained in SA-ASTM-CTLS-04/ SA-LTUL-CTLS-04 documents. This Flight Design SA requires verification of ground wiring Lane A connection to regulator of Lane A prior to next flight. This verification may be done by the Owner / Operator. If your aircraft is not affected, this must be noted in the logbook that the SA is complied with by non-affectivity due to presence of non-conformance. For affected aircrafts, full compliance with SA-ASTM-CTLS-04/ SA-LTUL-CTLS-04 must be carried out and so noted in the logbook.

If you have a CTLSi and did not get an alert Email Please go to our Contact us to be sure we have the correct email address.

Flight Design has made the Rotax ASB explicitly applicable to all the Flight Design aircraft types

the following link is to the Flight Design Bulletin.

(Reminder: Continued airworthiness regulations require the owner / operator to check for applicable Notifications frequently, considering airframe and all installed equipment manufacturer information!).

As per our production documentation, none of the engines installed ex factory is affected by the Rotax ASB. With this, our Safety Alerts require mandatory inspection of the aircraft only, when the engine has been exchanged after delivery of the aircraft from the factory, as only this way an affected engine could have been installed to the aircraft.

The original publication of the Rotax documents is available using the following links:

ASB affecting the Type Certified engine versions:

Alert Service Bulletin ASB-912-062 R1 / ASB-914-044 R1, March 05, 2013

Link: http://www.flyrotax.com/portaldata/5/dokus/d05638.pdf

ASB affecting the Ultralight and ASTM standard compliant engine versions:

Alert Service Bulletin SB-912-062UL R1 / SI-914-044UL R1, March 05, 2013

Link: http://www.flyrotax.com/portaldata/5/dokus/d05640.pdf

The attached SA´s are divided in different files according to the certification basis affected. Please select the documents applicable for your certification basis.

We spent best care in generating these documents to ensure that the information presented is adequate and correct. However, mistakes can never be excluded 100% and individual situations might require adjusted measures. Therefore, in case of any doubt, missing information or if a possible misunderstanding is expected, please do not hesitate to contact us. Our technical team will provide you with fast and direct support.

SB-ASTM-CTSW-10 Inspection of the Rescue System Rear Harness Connection.

Please note that this SB applies to CTsw from serial numbers 06-01-07 to 06-11-13 and the SB gives the owner the directions/instructions to make sure it has been complied with.

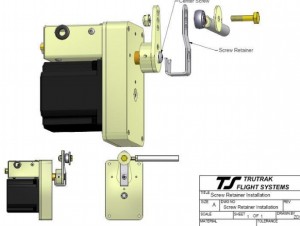

Trutrak Flight Systems will include the bracket with all new servos shipped with the current servo arm screw. This bracket will also be available to all customers with the current servo arm screw configuration as a field retrofit solution.

On the CTsw and CTLS we use several methods to determine fuel levels for proper pre-flight planning and in-flight management.

On the CTsw in Classic configuration we use the aluminum dipstick as the basic method for checking fuel, with the clear plastic sight gauges as an in-flight back up for determining fuel remaining in the tanks.

An official factory Service Notification been issued today on the subject of Information on the usage of Ethanol blended fuel. It provides specific directions to follow if you are using or have used Ethanol blended fuel. Much of what is stated duplicates the earlier Ethanol notice posted here in the FDUSA Owners section but it is formalized and now has recommendations that must be followed.

The Service Notification is in a new format that is soon to be described in detail on the maintenance support page. The format may look familiar to those of you who have seen the revised Rotax notices for the 912S engines. The idea is to make it easier for an owner or repairman to make certain that a specific model of Flight Design aircraft is in compliance with the factory maintenance and airworthiness notices. It may look a little confusing at first glance, but it is really quite simple. If you own a CTsw you will only need to look at notices for the CTsw and not notices for the original CT and older CT2K.

We will be updating the older notices to the new format and removing some that are no longer needed in the near future.

Ethanol has been in the news a lot lately and, as the result of phase separation, is believed to have contributed to the failure of a fuel filter installed in a CTSW.

Ethanol absorbs water and blends well with gasoline. However, too much water will overwhelm the ethanol’s ability to remain blended with the gasoline. Because ethanol mixes easier with water than gasoline, it will separate from gasoline and accumulate with the water at the lowest point of a system. The product in the tank will no longer be a homogeneous blend of ethanol and gasoline, but two layers of product; a layer of gasoline on top and an ethanol/water layer on the bottom. This is referred to as “phase separation.”

As many of you may be aware, one of the production changes requested on newer CT’s distributed in North America was the addition of a firewall blanket and oil hose sleeving in the engine compartment in order to provide additional fire protection and reduced cabin noise. These changes were implemented in late 2006. The original firewall is carbon fiber coated with fireproof epoxy resin.