BLOG

Saturday 1 April, 2023 5:39 am | News

Flight Design, and U.S. Importer Airtime Aviation are happy to report that they have enjoyed a successful Sun ’n Fun airshow in Lakeland Florida, USA.

Record crowds and excellent weather contributed to an overall positive atmosphere, but the Flight Design booth was busy due to the beautiful F2 LSA provided by New England region dealer, CHI Aviation of Portsmouth, New Hampshire.

“I am very impressed with the Sun ‘n Fun show said Flight Design CEO, Daniel Guenther. This is my first visit here and it is just great. I am also impressed with the dealer’s active contribution to our display. Airtime Aviation, World Aviation from South Carolina and CHI from New Hampshire have all been here speaking with customers, even Tom Peghiny, the former Importer, who is now a brand ambassador and consultant is here, said Daniel.”

The F2 on display is a fully loaded LSA model with top-of-the-line options including a Garmin 175 WAAS GPS navigator, a Garmin G5 backup display and the AMSAFE Airbag system. There is anticipation for the FAA to complete the validation process to bring the EASA certified F2 CS23 model to the USA. The FAA validation is expected later this year. The F2-LSA model is selling very well in the USA since its introduction in 2021.

“We are very pleased with the show and it means a lot for Daniel to come over to meet our staff and customers, Said Tom Gutmann Jr. Sun ‘n Fun is a big sales opportunity for us and great time for him to meet our existing customers who come by the booth and learn more about the market here.

With production beginning in Czech Republic, and new product developments, Flight Design is expecting a great Aero Friedrichshafen in April and EAA Airventure at Oshkosh in July.

Thursday 25 August, 2022 1:29 pm | Events

Our representative from Flight Design South East will be at the DeLand Showcase with a F2.

Aero Showcase at DeLand, FL 2022 will be provided by Aero Affinity Holding. This event is a traditional annual exhibition, focused on Sport Aviation. The Showcase is held at the DeLand Municipal Airport (KDED) in the city of DeLand, known as “The Athens of Florida” for its rich, creative culture featuring art venues, unique stores, international cuisine, night life and live entertainment. Plus, the weather in late October is perfect for a family fun Florida weekend.

The Showcase welcomes all aviation enthusiasts, of all ages — especially those just becoming interested in the Fun Side of Flying!

OUR LOCATION

We are strategically located at DeLand Municipal Airport, DeLand, FL (KDED), the capital of Sport Aviation and home of the busiest skydiving activities airport in the US. DeLand Airport is also the venue of one most prestigious annual Sport and Recreational aviation events in the US, the Sport Aviation Showcase.

DeLand Municipal Airport is also advancing a major Sport Aviation Enterprise: The DeLand’s Sport Aviation Village. This will be a premier location for manufacturers of recreational aircraft and related components. This will leverage DeLand as the greatest trend in Light Sport Aviation’s World and a center for recreational aircraft manufacturers, dealers, and aircraft owners.

Another side-note about our address: DeLand is the county seat of Volusia County and is located just 20 miles from Daytona Beach, home of the well known Embry-Riddle Aeronautical University which graduates hundreds of pilots and aeronautical engineers every year; also, DeLand is just 40 minutes away from Orlando, and one hour from the Space Coast and its Aerospace Cluster. This location is a key and strategic convenience for any aeronautical business when it comes to suppliers, skilled labor, research, and commercial connections.

Tuesday 25 January, 2022 6:57 am | Maintenance

Flight Design has released a new service bulletin regarding the installation of the BRS parachute system. In order to make sure it is the most current revision, it should be downloaded directly from the Flight Design Website. It can be found HERE. After going to that page, make sure you select either “CTLS” or “CTSW”, and then “ASTM”. Scroll down to find SB-ASTM-CTLS-20 or SB-ASTM-CTSW-17.

PLEASE READ THE SERVICE BULLETIN DOCUMENT IN ITS ENTIRETY. There are photos showing proper installation. If you have any concerns with the installation of your system, please consult your maintenance professional, or email photos of your installation to topservice@flightdesignusa.com. Please do not call Flight Design USA regarding this issue, as we will require photos to be emailed and reviewed.

Monday 21 June, 2021 8:13 am | Uncategorized

Dear Flight Design CTSW and CTLS(i) owners,

It has come to our and BRS Aerospace’s attention that on several aircraft, mechanics have not been following the parachute system installation instructions when reinstalling the parachute system. This has created an unsafe condition on several aircraft including parachute bridles stowed on top of the canister blocking the parachute, incorrect rocket pickup collar installation, and bridles caught in the main attachment carabiner. We are planning to issue a Service Bulletin to inspect for this but wanted to communicate this right away. There are approved re-installation directions on this website that must be followed exactly. Click on the aircraft model to download the instruction:

CTSW

CTLS

Friday 2 April, 2021 4:50 am | Uncategorized

Thursday 18 March, 2021 10:35 am | News

Flight Design USA has chosen Professional Instrument Courses (PIC) to assist in developing a simulator training course for the upcoming certified version of the new Flight Design F2, called the F2-CS in the United States. PIC is a Connecticut based company that travels to customer with their simulators and instructors, allowing a cost-effective and time-effective system for getting and maintaining an Instrument Rating.

“We are very excited to be working with PIC for our planned simulator syllabus for the F2-CS, which is planned to be sold in the USA as an IFR approved certified aircraft, said Flight Design USA President, Tom Peghiny. PIC has been in business for over 40 years now and there is a good reason, their focus on the client and their professional approach to Instrument training”.

Tuesday 15 December, 2020 8:27 am | News

Thursday 12 November, 2020 6:16 am | Uncategorized

Click HERE for the article.

Wednesday 28 October, 2020 6:24 am | Uncategorized

This article originally appeared in the October 2020 issue of Aviation Consumer magazine. All rights reserved.

PDF can be viewed HERE.

Click HERE to view accompanying video.

Friday 10 January, 2020 7:09 am | Uncategorized

Click HERE for the article.

Monday 25 November, 2019 11:02 am | Uncategorized

The new bulletin is not listed as an Alert Service Bulletin, but does require an inspection before next flight on the affected aircraft. Download the bulletin HERE (PDF).

Wednesday 4 September, 2019 7:31 am | Uncategorized

Wednesday 19 June, 2019 5:12 am | Uncategorized

Click HERE for the article.

Friday 14 June, 2019 5:06 am | Uncategorized

Click HERE for the article.

Wednesday 15 May, 2019 11:44 am | Uncategorized

Click HERE for information page.

Thursday 28 March, 2019 9:28 am | Uncategorized

When asking for the parts for the new service bulletin, please include your aircraft serial number and annual inspection due date (or if the plane is currently undergoing the inspection) in an e-mail to flightdesignusa@rcn.com

Thank you.

Friday 15 February, 2019 12:32 pm | Uncategorized

Click on the image to be taken to our CT Super Sport information page.

Friday 1 February, 2019 7:12 am | Uncategorized

Click on the image for the news article.

For more information on the CT Super Series, click here.

Wednesday 2 January, 2019 1:35 pm | Uncategorized

Flight Design USA is pleased to announce that Banterra Bank is now offering financing for Flight Design aircraft.

Mitch Loiselle, the relationship manager for Light Aircraft financing for Banterra has been working with our

industry for many years and is well versed in the needs of our customers. We are excited to be working with

a bank that supports our industry and wish them great success in 2019!

For more information:

Please visit our financing page at http://flightdesignusa.com/how-to-buy/financing/

Or visit Banterra’s website at https://banterraaircraft.com/flight-design/

Tuesday 2 October, 2018 8:45 am | Uncategorized

One of our owners flew his CTSW across the continental US. Read the whole story here: LINK

Monday 17 November, 2014 6:25 am | News,Owners

A safety Alert applicable to All aircrafts with Airframe Emergency Parachute System BRS 1350 HS installed, and with S/N up to F-13-09-04, C-11-11-02,A-12-04-33, included.

Please refer to This Alert

MANDATORY SAFETY ALERT

Aircraft with higher S/N are not affected.

Monday 23 December, 2013 7:21 am | Maintenance,News,Owners

Flight Design has issued a Mandatory Safety Alert (SA) issued December 19, 2013. For Fuel Injected CTLSi aircraft.

This Safety Alert requires you to determine, by reference to engine type – Rotax 912iS, if your aircraft has been affected. Detailed information is available on the Flight Design webpage: http://www.flightdesign.com/index.php?page=service, as contained in SA-ASTM-CTLS-04/ SA-LTUL-CTLS-04 documents. This Flight Design SA requires verification of ground wiring Lane A connection to regulator of Lane A prior to next flight. This verification may be done by the Owner / Operator. If your aircraft is not affected, this must be noted in the logbook that the SA is complied with by non-affectivity due to presence of non-conformance. For affected aircrafts, full compliance with SA-ASTM-CTLS-04/ SA-LTUL-CTLS-04 must be carried out and so noted in the logbook.

If you have a CTLSi and did not get an alert Email Please go to our Contact us to be sure we have the correct email address.

Monday 11 March, 2013 7:56 am | Maintenance,News,Owners

Flight Design has made the Rotax ASB explicitly applicable to all the Flight Design aircraft types

the following link is to the Flight Design Bulletin.

(Reminder: Continued airworthiness regulations require the owner / operator to check for applicable Notifications frequently, considering airframe and all installed equipment manufacturer information!).

As per our production documentation, none of the engines installed ex factory is affected by the Rotax ASB. With this, our Safety Alerts require mandatory inspection of the aircraft only, when the engine has been exchanged after delivery of the aircraft from the factory, as only this way an affected engine could have been installed to the aircraft.

The original publication of the Rotax documents is available using the following links:

ASB affecting the Type Certified engine versions:

Alert Service Bulletin ASB-912-062 R1 / ASB-914-044 R1, March 05, 2013

Link: http://www.flyrotax.com/portaldata/5/dokus/d05638.pdf

ASB affecting the Ultralight and ASTM standard compliant engine versions:

Alert Service Bulletin SB-912-062UL R1 / SI-914-044UL R1, March 05, 2013

Link: http://www.flyrotax.com/portaldata/5/dokus/d05640.pdf

The attached SA´s are divided in different files according to the certification basis affected. Please select the documents applicable for your certification basis.

We spent best care in generating these documents to ensure that the information presented is adequate and correct. However, mistakes can never be excluded 100% and individual situations might require adjusted measures. Therefore, in case of any doubt, missing information or if a possible misunderstanding is expected, please do not hesitate to contact us. Our technical team will provide you with fast and direct support.

Sunday 22 July, 2012 5:32 pm | Maintenance,Owners

SB-ASTM-CTSW-10 Inspection of the Rescue System Rear Harness Connection.

Please note that this SB applies to CTsw from serial numbers 06-01-07 to 06-11-13 and the SB gives the owner the directions/instructions to make sure it has been complied with.

Monday 8 November, 2010 4:15 am | Maintenance,News,Owners

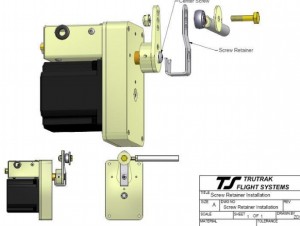

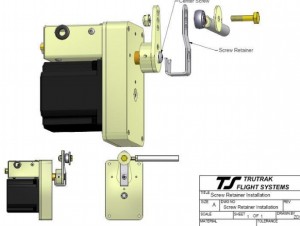

For Flight Design Aircraft Equipped with Trutrak autopilots:

Recent reports have suggested that there could be a problem with the new

integrated thread-locker servo arm screws that have been sent out for retrofit by

customers in the field. Reports indicate that the screw could back out of its hole

in the end of the servo shaft during normal usage. The suspected cause is residual

chemical thread-locker in the threads of the servo shaft which was the previous

method for locking the arm screws in place.

Trutrak Flight Systems will include the bracket with all new servos shipped with the current servo arm screw. This bracket will also be available to all customers with the current servo arm screw configuration as a field retrofit solution.

Thursday 16 October, 2008 1:52 pm | Maintenance,Owners

On the CTsw and CTLS we use several methods to determine fuel levels for proper pre-flight planning and in-flight management.

On the CTsw in Classic configuration we use the aluminum dipstick as the basic method for checking fuel, with the clear plastic sight gauges as an in-flight back up for determining fuel remaining in the tanks.

Read the rest of this entry »

Monday 22 September, 2008 6:27 pm | Maintenance,Owners

An official factory Service Notification been issued today on the subject of Information on the usage of Ethanol blended fuel. It provides specific directions to follow if you are using or have used Ethanol blended fuel. Much of what is stated duplicates the earlier Ethanol notice posted here in the FDUSA Owners section but it is formalized and now has recommendations that must be followed.

The Service Notification is in a new format that is soon to be described in detail on the maintenance support page. The format may look familiar to those of you who have seen the revised Rotax notices for the 912S engines. The idea is to make it easier for an owner or repairman to make certain that a specific model of Flight Design aircraft is in compliance with the factory maintenance and airworthiness notices. It may look a little confusing at first glance, but it is really quite simple. If you own a CTsw you will only need to look at notices for the CTsw and not notices for the original CT and older CT2K.

We will be updating the older notices to the new format and removing some that are no longer needed in the near future.

Monday 18 August, 2008 6:30 pm | Maintenance,Owners

Ethanol has been in the news a lot lately and, as the result of phase separation, is believed to have contributed to the failure of a fuel filter installed in a CTSW.

Ethanol absorbs water and blends well with gasoline. However, too much water will overwhelm the ethanol’s ability to remain blended with the gasoline. Because ethanol mixes easier with water than gasoline, it will separate from gasoline and accumulate with the water at the lowest point of a system. The product in the tank will no longer be a homogeneous blend of ethanol and gasoline, but two layers of product; a layer of gasoline on top and an ethanol/water layer on the bottom. This is referred to as “phase separation.”

Read the rest of this entry »

Monday 16 June, 2008 6:34 pm | Maintenance,Owners

As many of you may be aware, one of the production changes requested on newer CT’s distributed in North America was the addition of a firewall blanket and oil hose sleeving in the engine compartment in order to provide additional fire protection and reduced cabin noise. These changes were implemented in late 2006. The original firewall is carbon fiber coated with fireproof epoxy resin.

Read the rest of this entry »